小蓝视频-based carbon capture technology company Svante Technologies is broadening its reach to a global level through recent partnerships with major corporations, including 3M (NYSE:MMM) and Samsung Engineering.

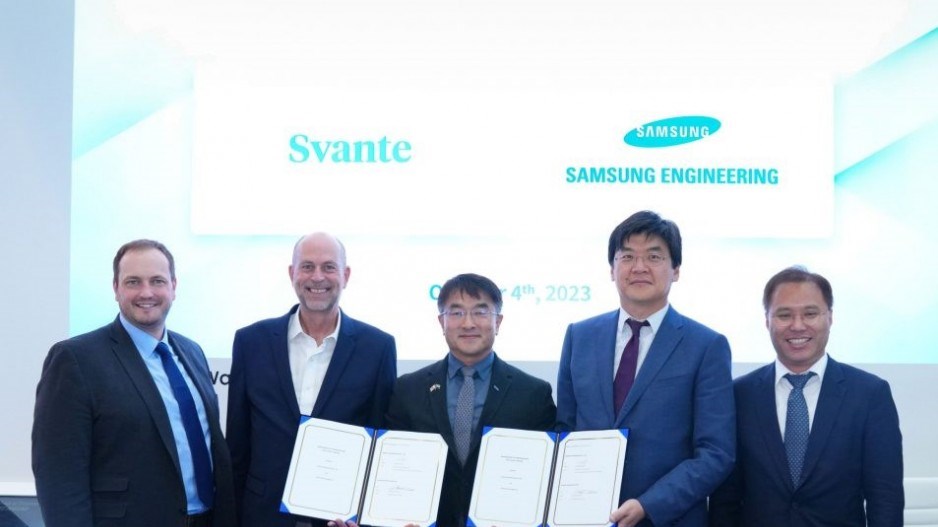

Earlier this week, Samsung Engineering and Svante signed a memorandum of understanding to collaborate on the commercial development of carbon capture, utilization and storage (CCUS) projects in Asia and the Middle East using Svante’s solid carbon capture filter technology.

Under the MOU, the companies will be targeting hard-to-abate industries, such as cement and steel-making, and hydrogen and fertilizer production.

Samsung Engineering is a global engineering, procurement, construction and project management company.

“Samsung Engineering’s 50 (plus) years of execution experience across the energy and industrial sectors will be invaluable as we continue to rapidly scale our operations and filter manufacturing capacity,” said Svante CEO Claude Letourneau.

Carbon capture has traditionally used a “wet” approach to capturing CO2 from industrial flue stacks: absorbent chemical solvents, which are then boiled to obtain the CO2. Svante developed a “dry” approach – adsorption, using a solid material to which the CO2 molecules cling. These filters can be used for both point-source and direct-air carbon capture technologies.

3M has more than a little experience with making these kinds of materials on a large scale, so earlier this year Svante and 3M announced they had entered a collaboration deal with the American manufacturing giant to produce rolls of material that ultimately will go into the filters that Svante will make at its new fabrication plant in Burnaby.

This week, 3M announced it is currently scaling up production of the Sorbents-on-a-Roll material that Svante will use to make its carbon capture filter, with field trials to begin in 2024.

3M makes a range of sorbent and filtration materials used in everything from diapers to home furnace filters. It also has expertise in roll-to-roll manufacturing – a process where a material (paper, for example) is placed onto large rolls.

“We can take those same skills, those same assets, manufacturing processes and apply them now to making the rolled goods for Svante’s filter pack,” Cory Sauer, 3M’s global carbon capture lead, told BIV News.

3M will make large rolls of the adsorbent materials in the U.S. and ship them to Burnaby where the material will be used to make carbon capture filters. Sauer said it takes 1 billion adsorbent sheets the size of a post-it note to make the filters capable to capturing 1 million tonnes of CO2 per year.

“It’s an enormous amount of material,” Sauer said. “It’s a lot of material, but it’s at a scale we are pretty familiar with.”